The 2024 AI Expo, held at the Expo Dome in Taipei Expo Park from April 24th to 26th showcased cutting-edge AI innovations in smart manufacturing. Three keynote speeches, each unveiling groundbreaking AI solutions, stole the spotlight and underscored the transformative power of artificial intelligence in revolutionizing traditional manufacturing processes.

WiAdvance's machine solution

First on stage was Kay Li, Vice President of WiAdvance Technology, a subsidiary of the Wistron Group. In her keynote speech, titled "Empowering Manufacturing Transformation: From Digitalization to AI," Li emphasized the profound impact of AI implementation on manufacturing efficiency, cost reduction, and environmental sustainability.

In 2021, WiAdvance obtained strategic investment and equity cooperation from Chunghwa Telecom. It focuses on providing application solutions based on public cloud platforms and hybrid cloud architectures and provides cloud, AI, and data as the core One-stop service.

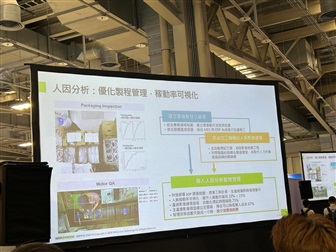

Li elucidated five key AI applications driving automated manufacturing, spanning from meticulous manufacturing inspection to proactive equipment maintenance, vigilant work safety alerts, streamlined supply chain management, and seamless automated communication. She emphasized that while AI doesn't entirely supplant human labor, it optimizes manufacturing by visualizing utilization rates and analyzing human factors.

AI enables swift identification of production bottlenecks, standardization of work hours, and rapid deployment of inspections according to established protocols. WiAdvance Technology boasts that such analysis can boost worker productivity by 10-15% and slash management time from days to a mere hour.

(Credit: DIGITIMES Asia)

Moreover, the AI model automates production scheduling by simulating the entire production process and timeline, leveraging data from the manufacturing company's ERP system. It then recommends necessary production equipment and forecasts delivery timelines for client orders.

Li shed light on WiAdvance's innovative approach to addressing customer concerns about equipment longevity. By accurately assessing the lifespan of factory tools based on real-time data, potential tool breakages that could impede production progress are preemptively averted.

Another standout AI solution showcased by Li was the use of generative AI to revolutionize defect detection processes. By integrating AI into production lines, the volume of products inspected per day skyrockets, and accuracy surpasses that of human inspections.

However, a prevalent industry challenge remains. Li says the manufacturing yield rate across all sectors in Taiwan averages around 90%. This means companies often encounter issues of insufficient data when they need to feed the machine data of various hypothetical defective scenarios the production may experience.

To tackle such an issue, WiAdvance devised a solution that uses genAI image technology to generate a wide range of potential defective product scenarios to teach the machine what to look out for.

Additionally, WiAdvance showcased another case study where generative AI was used to shorten their staff training process. The company says they used the AI tools of their in-house model to help translate the narration and subtitles of their product assembly demonstration videos for their Vietnam plant. After the initial translation, the video could then be re-translated into other languages such as English and Spanish.

While there exist many similar options of AI translation tools that could reasonably translate from Chinese to Vietnamese, uploading in-house training videos online may pose a potential risk of cybersecurity. WiAdvance said they significantly reduced labor costs—up to four times—as the AI translation tool executed 80% of the work, with only minor post-translation verification required by native speakers.

Coretronic's genAI-powered robots

Nore Chen, Chief Technology Officer of the Coretronic Intelligent Robotics Corporation (CRC), also took the stage at the 2024 AI Expo to deliver a keynote speech titled "Smart Manufacturing and AI Applications." In her presentation, Chen shed light on the expansive AI solutions by the Coretronic group's subsidiary.

(Credit: DIGITIMES Asia)

Coretronic Corporation founded in 1992, is the largest Taiwanese manufacturer of DLP projectors, interactive projection systems, image signal processing boxes, projection modules, LCD backlight modules, touch modules, and industrial and medical LCDs.

The main highlight of Chen's speech was the capabilities of the company's CoreSAM platform, powered by generative AI. This platform boasts an open vocabulary system, enabling it to recognize various objects without requiring constant retraining when transitioning to different environments or scenarios. Notably, it demonstrates resilience to variations in lighting and object size, making it applicable across diverse domains such as highway car tracking, smart factories, logistics, displays, controls, and cloud applications.

At the heart of the platform lies a fleet of Autonomous Mobile Robots (AMRs), including pallet trucks, stackers, reach trucks, high lift trucks, and rollers. These robots are seamlessly integrated with a flexible software platform designed to oversee vehicle management, logistics, and manufacturing processes.

Coretronic's AMR core technology excels in visual perception, motion control, and traffic management, equipped with multisensory systems akin to those in autonomous cars. These systems utilize 2D and 3D maps continually updated with real-time geographic information.

(Credit: DIGITIMES Asia)

Chen elaborated on deploying these AMR vehicles in Coretronic's intelligent factory in Suzhou, China, since August 2022. The AMR forklifts in this facility boast advanced AI image recognition capabilities, enabling tasks such as identifying storage location occupancy, assessing shelf heights, correcting pallet alignment, and reading QR codes.

Expanding beyond logistics applications, CRC's CoreSAM system extends its reach to AI drones. With an inference speed of 80 frames per second (fps), the AI system demonstrates prowess in detection, item coordination, flight control navigation, and seamless identification of moving car models. Local governments have leveraged these AI drones for diverse tasks, including slope identification, silt and oil pollution monitoring at sea, and traffic surveillance on highways.

(Credit: DIGITIMES Asia)

Chen says before the integration of GenAI, the source code of one AMR vehicle can amount to thousands or even hundreds of thousands of source code lines. But now with generative AI, the number of code lines of those vehicles has been decreased to hundreds, as many of the commands are now being generated instantly just as how ChatGPT responds upon receiving prompts from users.

Solomon's AR+AI vision

Last but not least taking the stage to share how their AI solutions have helped optimize manufacturing was the Visual Business Division Product Vice President of Solomon Technology Corporation, Michael Lee. His keynote speech, titled "Emerging Trends in Smart Manufacturing: Enhancing Factory Efficiency with AI Vision," illuminated the company's ambitious efforts to address prevailing challenges in manufacturing.

Established in 1973, Solomon Technology Corporation has garnered global recognition for its expertise in 3D vision systems and industrial AI. Renowned for engineering cutting-edge 3D cameras and industry-leading deep learning software platforms, Solomon boasts AI solutions renowned for their high precision, swift implementation timelines, seamless multi-device integration, and scalable AI models.

In recent years, Taiwanese factories have grappled with a slew of accidents and operational issues stemming from lapses in standard operating procedures. Lee underscored the prevalent risks faced by modern factories, including human errors in management, meter readings, and communication breakdowns leading to delays or maintenance oversights. Relying solely on manual inspections conducted by workers armed with clipboards has limitations.

Solomon introduced its AR + AI Vision System, META-aivi, to confront these challenges. Positioned as an Augmented Intelligence solution, META-aivi embodies a powerful synergy between Artificial Intelligence (AI) and human intelligence, enhancing human capabilities rather than replacing them.

(Credit: DIGITIMES Asia)

The system boasts versatility, compatible with numerous smart devices ranging from smartphones and tablets to IP/body cameras, drones, robots, and AR glasses. Deployed across diverse sectors spanning manufacturing, semiconductors, chemicals, electronics, food processing, construction, and aviation, META-aivi seamlessly integrates with the factory's management system.

Equipped with AI-enabled cameras, the system captures real-time data from meters and machinery, wirelessly transmitting pertinent information while conducting routine checks to ensure optimal equipment functionality. Moreover, it guides workers through tasks using predefined standard operating procedures akin to a video game, alerting relevant units and systems in case of anomalies.

(Credit: DIGITIMES Asia)

Lee showcased how Solomon AI enhances the visibility of machinery readings, even amidst blurriness or poor color contrast, facilitating efficient data collection and record-keeping. Furthermore, the system is vital in ensuring workplace safety by detecting adherence to safety protocols and appropriate gear usage among staff.

While the scenarios demonstrated at the expo merely scratch the surface, Lee emphasized the overarching goals of improving operational efficiency, expediting onboarding processes for new hires, enhancing workplace safety, and offering real-time remote assistance to field personnel.