Detection not only safeguards the quality of products, but it can also discover flaws early in the production line through detection in key links – and further prevents the waste of manpower from continuous processing of defective products.

The smart factory solution from ASUS AIoT which integrates AI, optics, IoT, and other technologies, has helped many manufacturer customers from different fields optimize the efficiencies of their production lines. Recently, this solution has been launched overseas for the first time to help a major motherboard manufacturer in China, Amertek Computer, Co, build a smart detection system to help the company reduce detection time and optimize the scheduling of human resources.

ASUS established the ASUS IoT business group in 2019, and ASUS as a whole now retains nearly 1,000 engineers dedicated to the development of IoT and AIoT hardware and software. Under the framework of Industry 4.0, ASUS IoT develops B2B IoT and AIoT hardware and software integration services.

Amertek was founded in 1994 and mainly manufactures computer mainboards. Its customers include international manufacturers of large servers and industrial computers. For its motherboard production lines, Amertek relied on manual visual inspection to detect flaws such as improper placement, missing components, skewness, and polarity reversal of components on the dual-inline package (DIP) line. This operation method produced has several pain points that are not easy to overcome.

For starters, inspection personnel need to focus on tiny and complex components for long periods of time, which can easily cause visual fatigue and affect the accuracy and consistency of inspections. Manual visual inspection also relies on personal judgment, and different personnel may have different inspection standards, resulting in inconsistent inspection results.

Then, when production quantity is increased, the efficiency of manual visual inspection is low and is unable to meet rapid production needs. Subsequently, when missed components enter the next production link and then problems are discovered, they need to be reworked or repaired, which causes increased cost and prolonged production cycles, affecting the production pace and product delivery times directly.

Finally, the professional requirements for visual inspection works are relatively high and require long-term training and accumulation of experience to reach the inspection standard. In addition, due to the monotonous nature and high pressure of the work, the turnover rate of the staff is also greater compared to other workstations, and this causes the recruitment and training costs of enterprises to remain high.

In order to soothe these pain points and more, Amertek decided to introduce a smart factory solution from ASUS AIoT. Since the production systems and processes of each manufacturing field are different, the ASUS IoT team provided a comprehensive service – from specification to build and installation.

Numerous meetings were held during the early stages of system introduction to evaluate the specific requirements of Amertek and restrictions of the existing production processes. ASUS IoT engineers also visited Amertek's manufacturing site to understand the conditions of the production lines.

Then, an AIoT solution was tailored according to the specific process requirements of Amertek, including customization of software and hardware tools, industrial camera configurations, optimization of image-processing algorithms, system integration and adjustments, and more. The ASUS IoT system accurately responded to the specific challenges of the production lines.

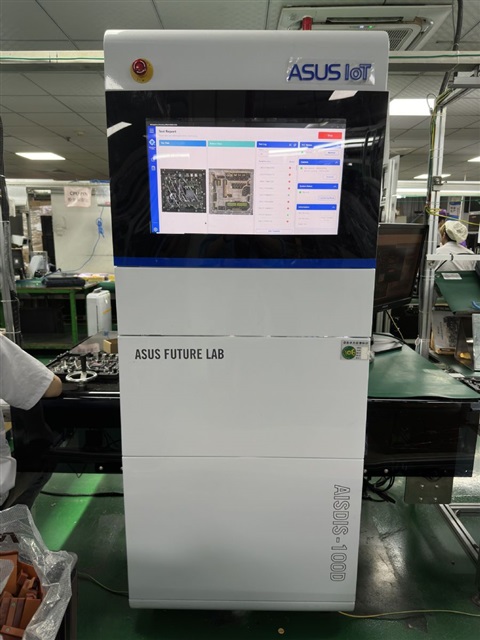

Under the service of the ASUS IoT team, Amertek's current AI vision-inspection solution, AISDIS-100D, is equipped with industrial cameras that can scan both the front and back sides of motherboards at the same time. This solves the problem of manual visual inspection being able to inspect only one side of the mainboard, often resulting in missing the flaws on the other side.

In addition, the AI algorithm developed by ASUS IoT can analyze the images collected by the industrial cameras and compare them with the images of the qualified and defective products in the database, vastly increasing the accuracy of inspection. The defect rate of the products on the production line was 3% during the early stages of introduction and had reduced to 1% after the introduction – significantly reducing material waste and human resources. The maintenance and rework costs of products also decreased.

In terms of manpower scheduling, through the ASUS IoT AI vision-inspection solution, Amertek reduced the human resources required for inspection from the original two workers to one – and the transferees were moved to more satisfying jobs. By reducing necessary personnel by half, the inspection efficiency improved: the original manual operation took approximately 17 seconds per piece, and was cut to 15 seconds – not including the rest times required to alleviate eye fatigue. Also, the machine-learning model built into the ASUS IoT system can self-learn and adjust continually to quickly respond to the various production changes, maintaining the consistency of inspection quality for long periods of time.

In terms of future plans, Amertek is currently cooperating with ASUS AIoT to develop an AI-powered review system that can be used for complex quality-control tasks such as precise flaw classification and detailed error analysis. Also, for specific problems such as mainboard deformation, Amertek plans to introduce professional board inspection systems to ensure that the products shipped from the factory can meet the highest physical specification standards.

From the long-term goal and strategy perspective, Amertek plans to continue to expand and introduce the applications of ASUS IoT vision-inspection solution into its production lines – deepening its cooperation with both ASUS IoT and the wider ASUS group to expand its market competitiveness.

For more product information, please refer to iot.asus.com.

ASUS AISDIS 100D, equipped with industrial cameras capable of simultaneously scanning both sides of a motherboard and a proprietary AI algorithm, significantly improves inspection accuracy and reduces waste in materials and labor costs