In the face of the global net-zero emissions trend, Taiwan's manufacturing industries will need to provide comprehensive carbon emissions data to meet government regulations and customer needs. However, it is fairly difficult to collect comprehensive machinery data without affecting the operation of production lines. Built with LoRa technology on LPWAN (low-power wide area network), Blutech's NeVerLoSs LoRa and WSDMS (Wireless Sensor Data Management System) can help manufacturers set up industrial control dashboard and energy consumption analysis platforms quickly, which is the first step in digital transformation.

For data collection of factory systems and production line equipment, Blutech co-founder/marketing director, Deral Chen pointed out that some manufacturers have set up data acquisition systems early on. After Germany formulated the Industry 4.0 initiative in 2011, the first step for the operational systems of the Industrial Internet of Things (IIoT), which is the backbone of smart manufacturing, is to obtain data of OT devices. Various smart functions have since been developed thereof. However, most of the data collected during this period was mainly pertaining to temperature, vibration, etc., while carbon emissions data was mainly gathered from electricity data. As such, further attention in this area is warranted.

Deral further pointed out that with increasingly stringent requirements for net-zero emissions imposed by the global market and supply chain, manufacturing industries need data acquisition and analysis systems which can be readily adopted, and Blutech's products and services can meet their demands. The company's solution consists of NeVerLoSs LoRa and WSDMS. They operate through the use of a LoRa transmission chip, which is supported by a proprietary module and the NeVerLoSs LoRa protocol. They connect equipment gauges around the factory and energy data is then monitored through the WSDMS.

Deral explained that there are several reasons for choosing LPWAN. First, it is not easy to install wiring in a manufacturing site. Therefore, the best way to increase efficiency of the set-up is to use wireless transmission. The regular wireless local area network (WLAN) is susceptible to interference from metallic materials and electromagnetic waves in factory equipment. Furthermore, its bandwidth would have been too large. Whereas, LPWAN has a long transmission range and its bandwidth is appropriate for control dashboard systems that only need to transmit simple signals, making it the first choice for such systems. The reason for adopting LoRa among various LPWAN standards is that it has been adopted by large global enterprises such as Amazon. Its reliability has since been proven by the market. Furthermore, LoRa's built-in AES-128 encryption system can also significantly reduce the probability of data hacking. Underpinned by these two features, Blutech has developed its NeVerLoSs LoRa technology, which transmits data over a distance of several kilometers and in collision-free packets, ideal for dashboard data transmission.

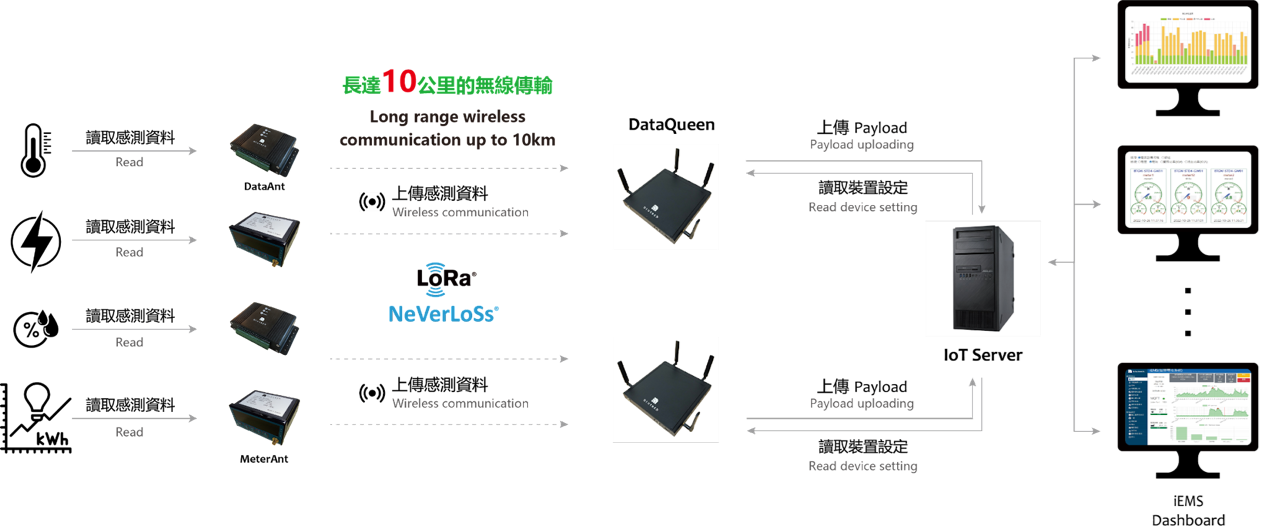

Paired with WSDMS, NeVerLoSs LoRa was developed by Blutech specially for manufacturing sites. The system consists of the Data Ant (data acquisition unit), Meter Ant (IIoT electricity gauges) and Data Queen (IoT gateway), which are able to acquire the electricity consumption data of factory equipment and display it on a dashboard, before transmitting it to the back-end system according to the preset frequency and priority. NeVerLoSs LoRa is able to help the management keep track of the data.

Via NeVerLoSs LoRa transmission technology and the WSDMS, Blutech has created a standardized one-stop energy data and sensor data acquisition system. Deral went on to say that the current process of constructing a data acquisition system for manufacturers is mostly performed by system integration companies. They would first take inventory of a manufacturer's needs, and then look for suitable hardware on the market and build the system using their own software. Although such customized system can meet the manufacturer's need at the time, the complexity of the hardware and software sources will cause numerous problems in the subsequent maintenance, upgrading and expansion. In addition, the cost of customized design is also higher, which is not necessarily the best choice for small- and medium-sized manufacturers with limited resources.

Blutech's standardized system is designed to solve the aforementioned problems. Since the data acquisition methods of factory equipment are fairly similar, its standardized system can meet most, if not all, needs. It only requires simple configuration and installation to go online. Meanwhile, future maintenance and expansion will not be restricted by a specialized system, and the cost is far lower than that of a customized design. With the advantage of a standardized product, Blutech's one-stop service can help manufacturers implement data acquisition and transmission systems quickly, so that customers can have a electricity data visualization system within a short period of time and meet market demand for carbon emissions data. Supported by sensor data, customers can quickly adopt applications such as energy management, energy performance indicators, water resource management and carbon inventory through Blutech's comprehensive SaaS service platform within the WSDMS infrastructure. This is equivalent to deploying and expanding several systems all at once.

Blutech has since helped many manufacturers set up factory-wide data acquisition systems. Far Eastern Fibertech, which produces high value-added nylon fiber products with advanced equipment and textile technology, has been relying on Blutech's WSDMS since 2015. Connected using NeVerLoSs LoRa transmission technology, Far Eastern Fibertech has maintained a very low failure rate for the past eight years, while continuing to expand its systems. In addition, many other manufacturers in various industries have also adopted the power monitoring system with the assistance of Blutech.

Blutech has built a reputation for its carbon data acquisition technology and solutions. Chen recalled that when Blutech was founded, domestic entrepreneurship was still in the infancy stage and there were no mechanisms in place to matchmake new startups with the capital market. All teams, including Blutech, had to figure things out themselves. Subsequently, with the help of government policies, financial institutions' understanding of new startups improved, and their willingness to inject capital and related mechanisms were enhanced. These changes were crucial for entrepreneurs. Thus, Chen hopes that Taiwan's entrepreneurial environment will become more friendly, so that the startup success rate can be boosted, thereby continuing to breathe life into the country's economic development.

Blutech's comprehensive solution framework. The SaaS platform (right) includes energy management, energy efficiency indicators, waste water flow management and carbon inventory.