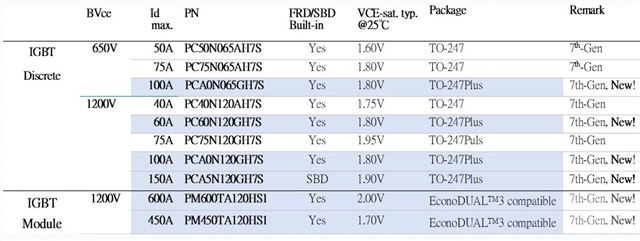

After successfully launching the 7th generation Micro-Pattern Trench (MPT) technology-based discrete IGBT new products in Q2 2024, PARA LIGHT ELECTRONICS CO., LTD. (Referred to as"Para Light" hereafter) recently announced its plan to introduce six additional products in Q1 this year. These new offerings will target applications in medium-to-high power servo motor drive control, uninterruptible power supply (UPS) systems, solar inverters, industrial induction heating, energy storage, and smart grid-connected systems.

The product lineup will include four high-performance discrete devices in TO247-3Plus packaging and two high-power modules featuring a half-bridge circuit structure, which is compatible with Infineon's EconoDUAL™ 3 (ED3) package. Leveraging advanced 7th-generation MPT-IGBT chip design and manufacturing technology, these new products will provide the application market with exceptional solutions for enhanced efficiency and stability.

Para Light's IGBT Product Portfolio includes six new products, designed and manufactured using 7th-generation Micro-Pattern Trench (MPT) chip technology. *Note: PCA0N065GH7S is a custom product and is not available for the mass market at the moment. Credit: Para Light

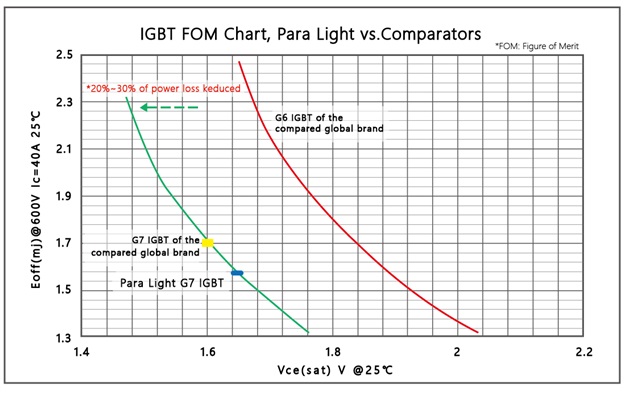

Performance Benchmarking – Para Light's 7th-Gen IGBT vs. 6th- and 7th-Gen IGBTs of a global leading brand. Para Light's 7th-Gen IGBT solutions deliver performance on par with the global Tier-1 brands' 7th-Gen IGBT products while outperforming 6th-Gen counterparts by 20–30%. Credit: Para Light

In these four TO247-3Plus packaged products, the metal surface area for heat dissipation has increased by approximately 18% compared to the standard TO247-3 package. This enhancement effectively reduces the chip's thermal resistance and operating temperature, thereby extending the lifespan and stability of customers' power systems while also lowering cooling system costs. Notably, a new solution with a 1200V/60A specification will soon be available in the standard TO247-3 package (tentatively designated as PC60N120AH7S), offering customers more options when designing power systems.

For higher-power applications, Para Light has also introduced two high-performance IGBT module products with power ratings of 1200V/600A and 1200V/450A. Both modules adopt a standard half-bridge configuration and incorporate built-in negative temperature coefficient (NTC) resistors to provide reliable over-temperature protection. Furthermore, the flat packaging, which is compatible with Infineon's EconoDUAL™3 (ED3) package, significantly enhances the power density of the overall power system.

Eric Hung, Deputy General Manager of Business and Marketing for Para Light's Power Semiconductor Division, stated that whether in discrete or module IGBT products, Para Light is committed to using the advanced seventh-generation MPT chip technology for both design and manufacturing. In addition to delivering higher operational efficiency, our G7th IGBT technology achieves exceptionally high chip production yield, underscoring the mature, reliable, and stable quality of Para Light's IGBT products—key attributes that set the brand apart in a competitive industry. Moreover, the IGBT products offer several advantages, including a maximum operating junction temperature of up to 175°C and excellent short-circuit current capability and overload test performance under high-temperature conditions. These features ensure that customers' power systems maintain high stability and an extended service life, even under full load or harsh environmental conditions. Additionally, the wide range of applicable switching frequencies enables parts consolidation, effectively reducing procurement costs.

David Ma, the Chairman of the Board, emphasized that since IGBTs are key components in various power electronic systems, their performance and quality stability not only directly affect overall system performance but also play a critical role in material management and reducing the hidden costs associated with system failures. Listed on the Taiwan Stock Exchange and a global leader in LED design and manufacturing since its establishment in 1987, Para Light's core competencies in continuous product innovation and strict in-house quality control have been central to maintaining its competitive advantage. In recent years, the company has further leveraged these strengths to expand into the power semiconductor sector. As one of the few industry brands with an advanced seventh-generation IGBT power transistor product line and packaging and test plant, Para Light's IGBT products offer significant value by delivering enhanced efficiency and stability to customers' power systems.

Para Light Electronics holds ISO 14001, ISO 9001, and IATF 16949 quality management certifications. Its power semiconductor products undergo JEDEC's six major reliability tests, and all critical processes—from incoming inspection to product shipment—are rigorously controlled through SPC. The proven stability and consistency of these products have resulted in high market acceptance, with several strategic customers in the regions of Greater China, Taiwan, and India continuously integrating Para Light's solutions into applications such as industrial servo motor drive control, UPS systems, industrial solar inverters (PV inverters), and energy storage power management equipment. Looking ahead, the company plans to extend its product applications into electric vehicle DC fast-charging solutions.

Para Light Electronics holds ISO 14001, ISO 9001, and IATF 16949 quality management certifications. Its power semiconductor products undergo JEDEC's six major reliability tests, and all critical processes—from incoming inspection to product shipment—are rigorously controlled through SPC. The proven stability and consistency of these products have resulted in high market acceptance, with several strategic customers in the regions of Greater China, Taiwan, and India continuously integrating Para Light's solutions into applications such as industrial servo motor drive control, UPS systems, industrial solar inverters (PV inverters), and energy storage power management equipment. Looking ahead, the company plans to expand its product applications into electric vehicle DC fast-charging solutions soon.