Rayleigh Vision Intelligence (RVI), a Taiwanese technology startup company, will showcase several groundbreaking MicroLED technologies at the Consumer Electronics Show (CES) 2025. These innovations include the newly introduced "Smart+ MicroLED AI Manufacturing Technology," "XNOW AI MicroLED Bin Mixing," which can reduce the time required for mass transfer and repair processes to one-third of the current standard processes, this significantly accelerates the mass production of Micro LED. RVI also displays the world's only "Stacked MicroLED Chips" that can achieve standalone single-chip sizes below 100 μm, demonstrating the company's expertise in AI-assisted manufacturing and advanced packaging techniques.

Combining Advanced Processes and AI Technologies to Revolutionize MicroLED Manufacturing and Accelerate Industry Mass Production

RVI focuses on innovative MicroLED technologies, striving to solve multiple bottlenecks in MicroLED mass production, such as high-cost mass transfer processes, insufficient production capacity, and panel color inconsistency. The company's main focus is on innovative technologies in MicroLED manufacturing, including AI-optimized process products and new types of MicroLED chips. Additionally, RVI plans to launch full-color micro-display products suitable for AR/VR glasses and MicroLED-based silicon photonic communication components in the second half of the year, aiming to further expand the MicroLED business landscape.

The three key technologies showcased by RVI at CES include:

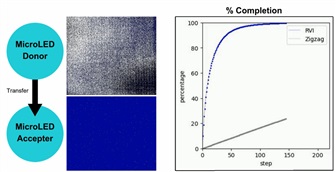

1. Smart+ MicroLED AI Manufacturing Technology: RVI extensively introduces AI algorithms into the MicroLED manufacturing process, revolutionizing traditional mass transfer techniques, optimizing repair paths and methods, and improving process efficiency, which has already improved manufacturing efficiency for their customers by more than twofold, helping them reduce the production costs of MicroLED, and accelerating the adoption of MicroLED applications in mainstream markets.

2. XNOW MicroLED AI Bin Mixing Technology: Addressing the inherent non-uniformity in the LED manufacturing process, this technology utilizes AI to assist in chip sorting, effectively eliminating brightness and chromaticity defects, significantly improving panel uniformity, achieving high-quality displays at lower costs, and shortening mass production time.

Speed comparison between RVI's XNOW Bin-mixing and traditional scanning pairing Bin-mixing method (simulation). Credit: RVI

3. Stacked MicroLED Chips: To meet the 8K ultra-high resolution requirements of next-generation AR/VR devices, RVI has developed an advanced packaging process for vertically stacked MicroLED RGB chips. The exhibited 70μm*70μm MicroLED-in-Package chip is currently the world's smallest standalone stacked MicroLED chip, suitable for applications such as smartwatches, smartphones, and monitors.

RVI's showcase of the world's smallest standalone stacked MicroLED at CES is expected to change the current MicroLED production methods Credit: RVI

Dr. He, Jr Hau, Founder and Chairman of RVI, stated, "MicroLED technology is approaching mass production, but high costs remain a significant challenge. In response, RVI has established an artificial intelligence (AI) department to leverage AI in solving traditional manufacturing process difficulties, substantially improving process efficiency and reducing costs. At the same time, to achieve ultra-realistic AR/VR experiences, 8K or higher resolution MicroLED micro-displays are required. The industry should adopt advanced semiconductor packaging techniques and move towards three-dimensional development when chip sizes approach their limits."

In the future, RVI plans to expand the applications of its MicroLED technologies and AI solutions to areas such as AR/VR, silicon photonic communication components, and smart factory solutions. The company also aims to establish a fully AI-assisted automated MicroLED production line in the second half of 2025.

Credit: RVI

Exhibition Details

Date: January 7-10, 2025

Location: Eureka Park, Hall G, Venetian Expo, Booth 62501 (Taiwan TTA Exhibition Area)